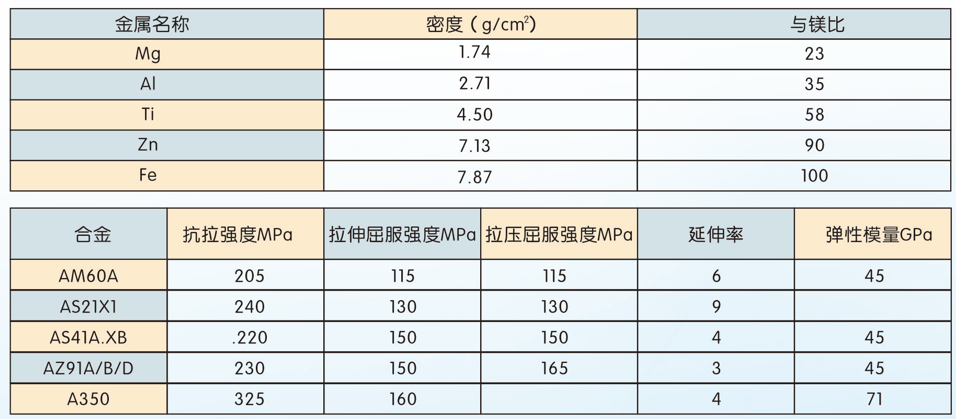

Product World

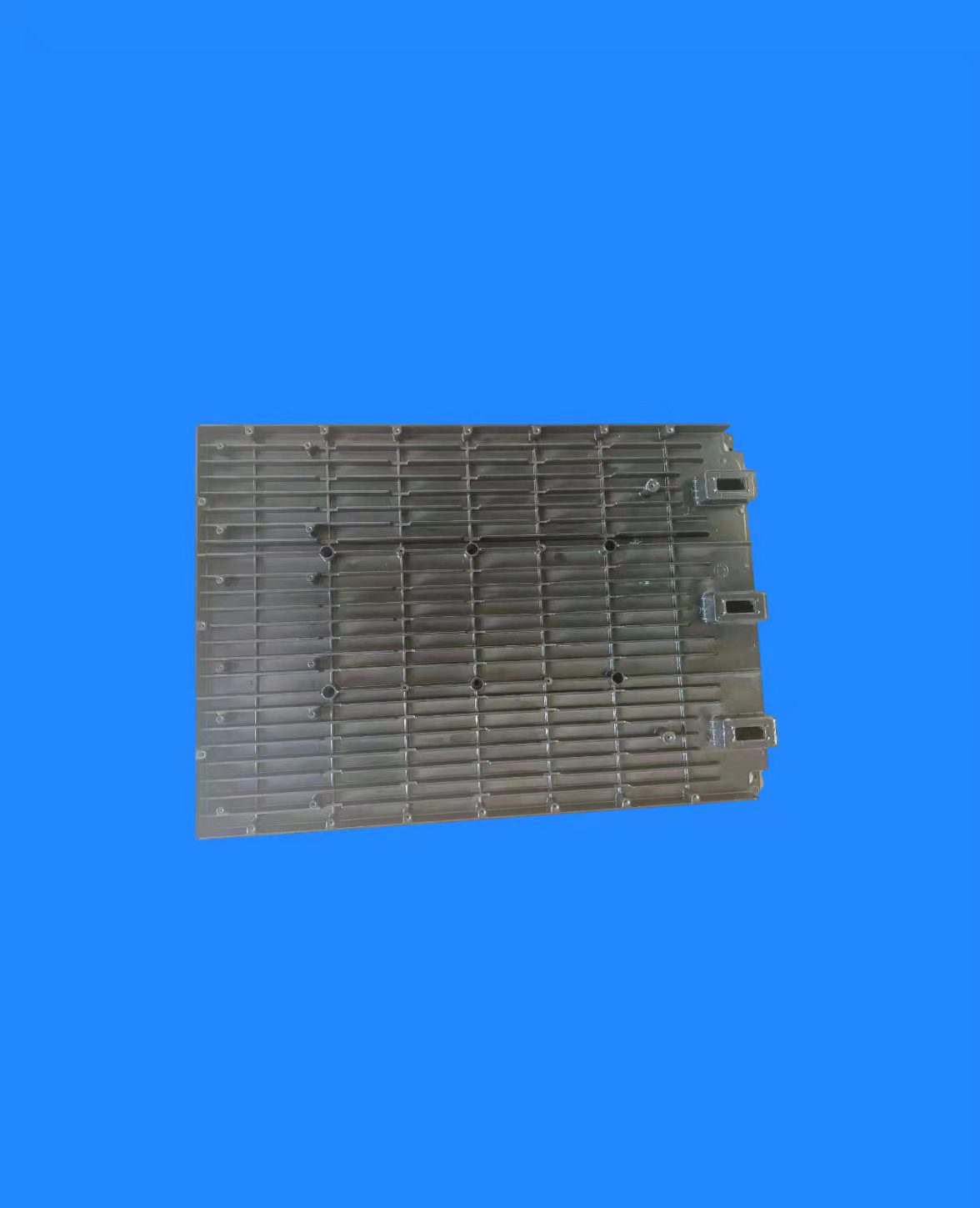

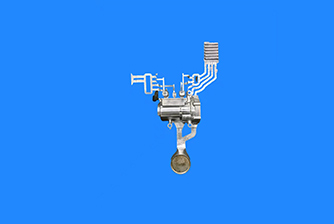

Magnesium alloy

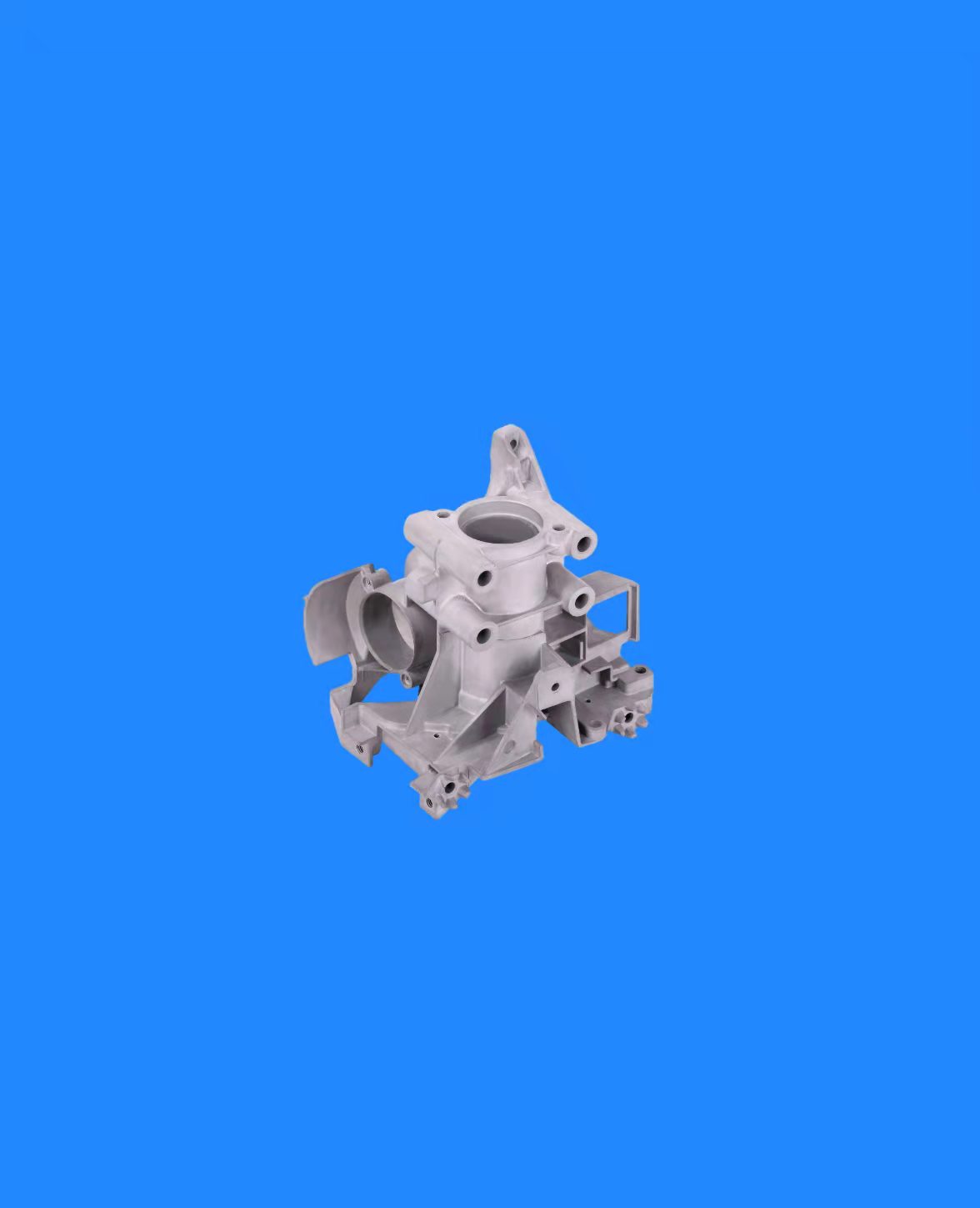

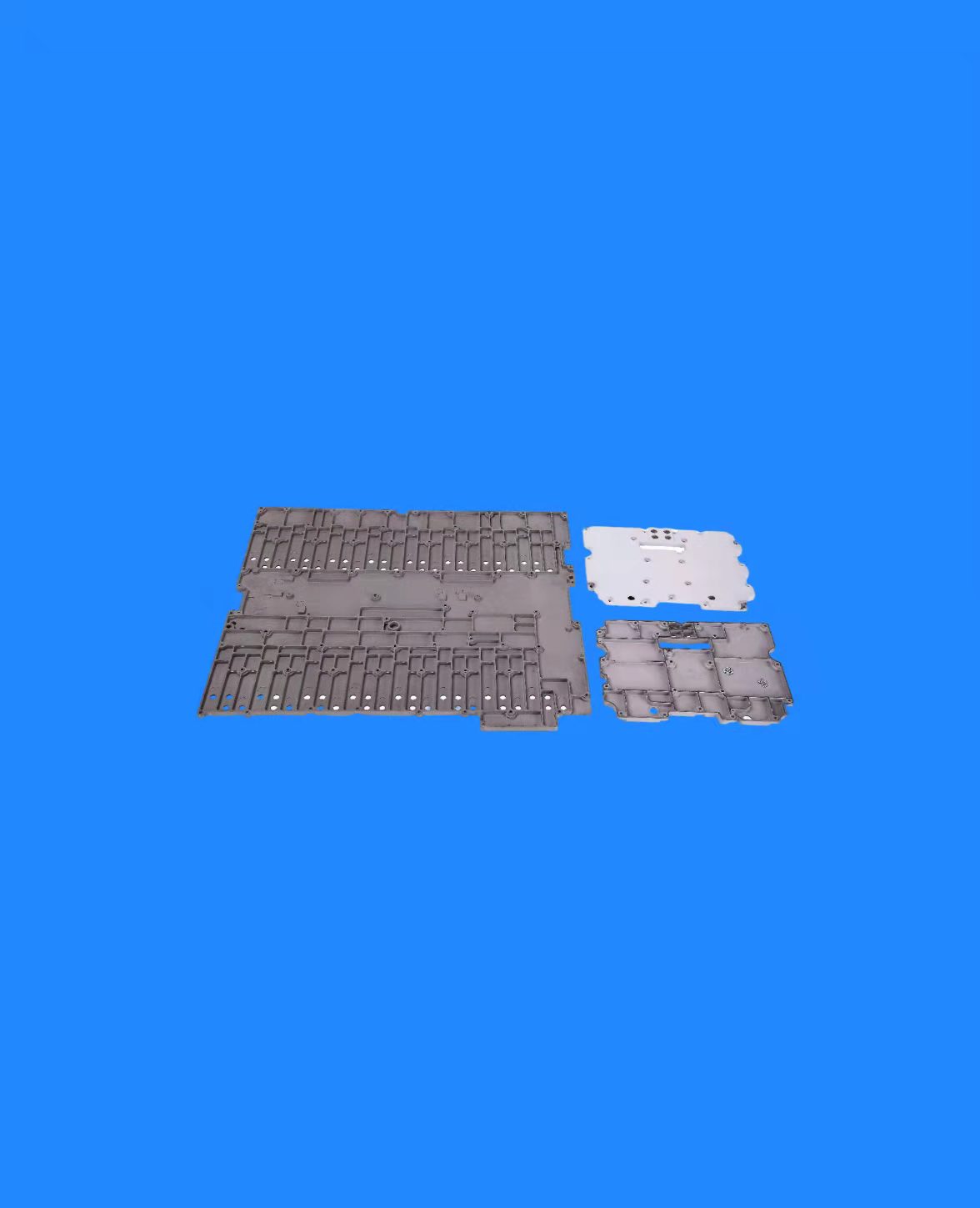

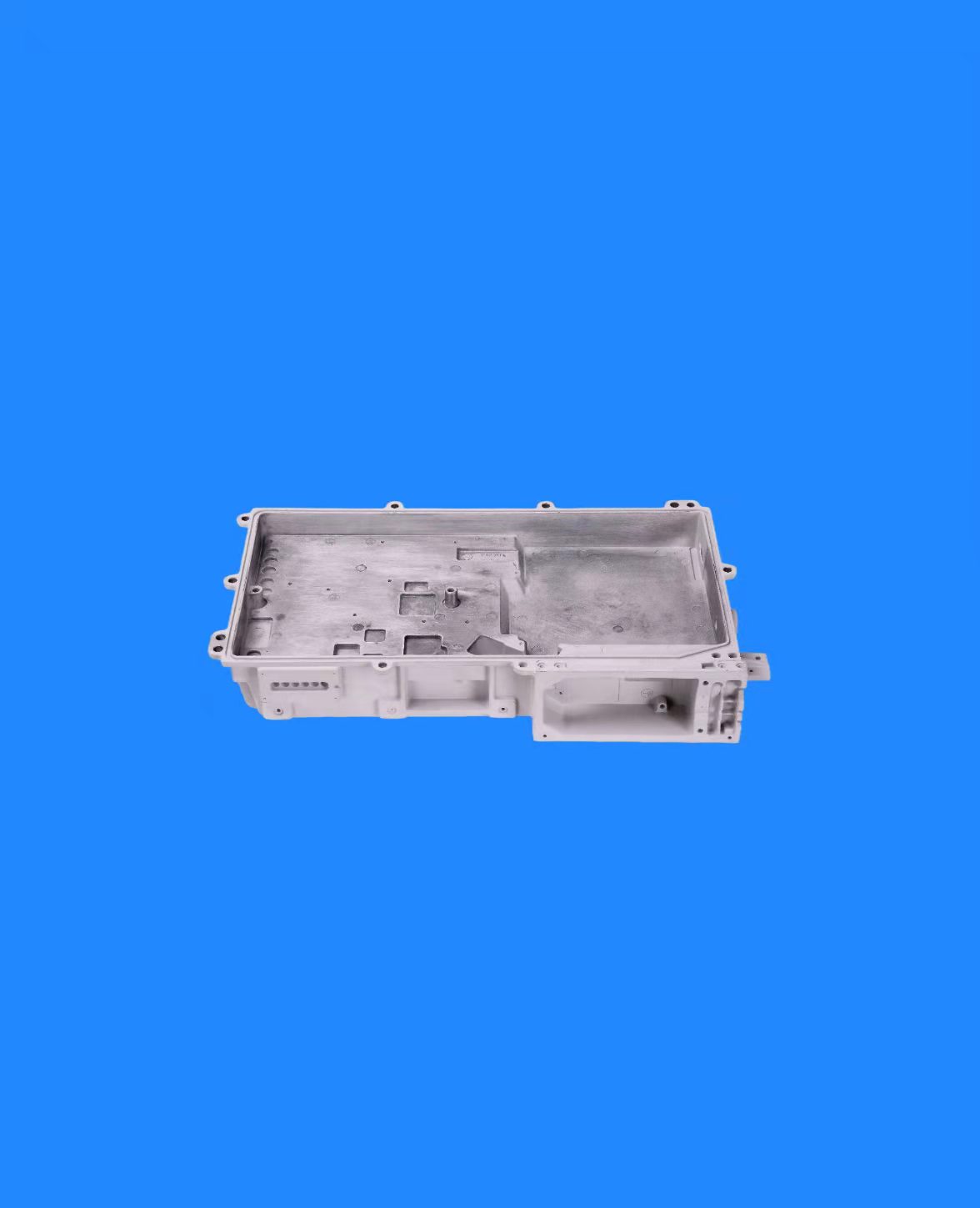

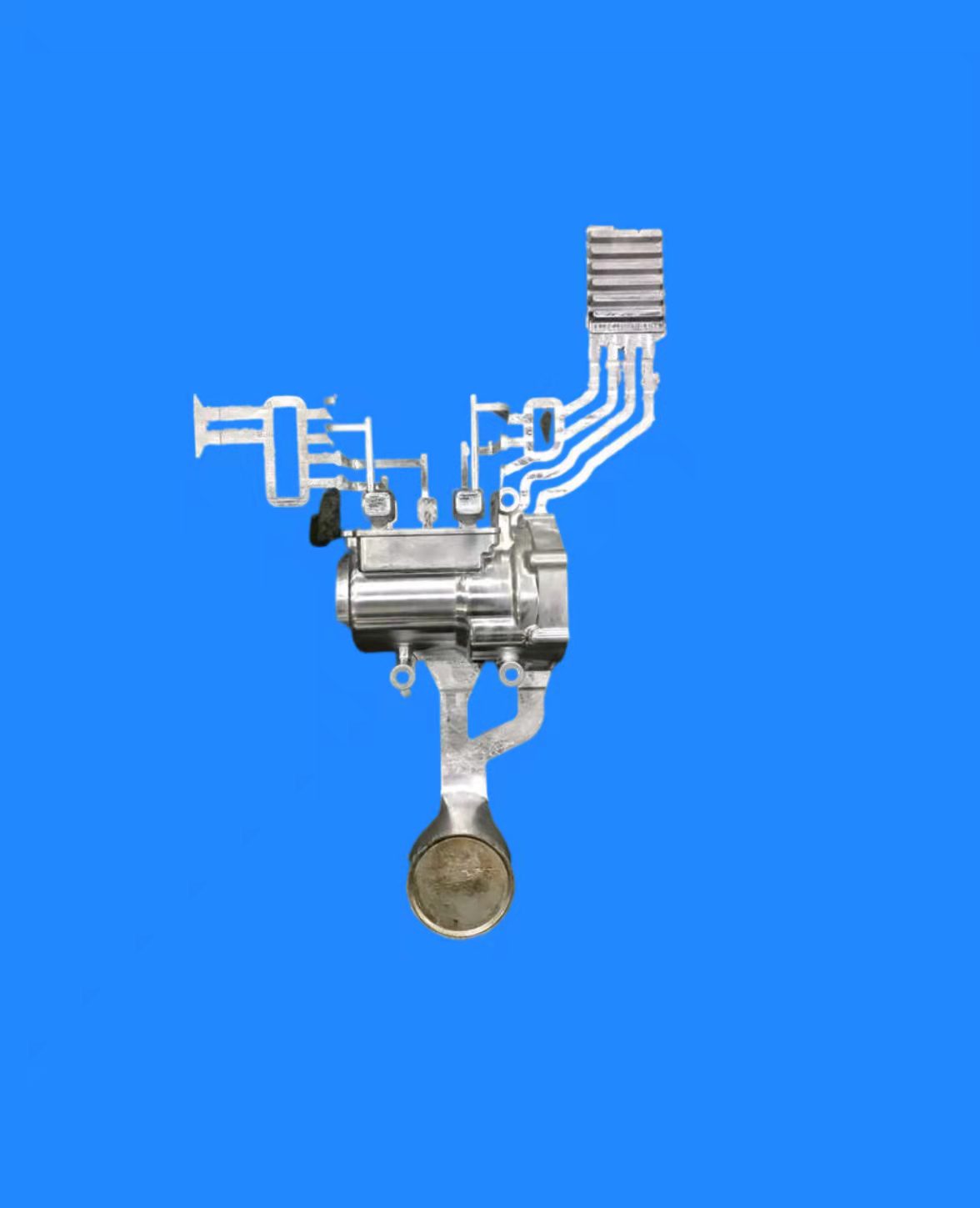

The company focuses on the research, development and application of magnesium alloy andaluminum alloy materials, and has a professional mold design and manufacturing team,committed to the development and production of lightweight pre cision die casting parts. Is a collection of mold design and manufacturing, product research and development, production and sales of one of the national high-tech enterprises. The products are mainly used in automobile parts, communication base station, new energy, construction, military industry, power tools and other fields.

1. Low density. The density of AZ9 1 magnesium alloy, the lightest metal in commonuse,is 1.81-3g.cm, about 2/3 of aluminum and 1/4 of zinc. Less than a quarter of the density of steel or cast iron, close to the density of engineering plastics. For a polycarbonate composite containing 30 percent glass fiber, magnesium is no more than 10 percent. Therefore, the use of magnesium alloy can effectively reduce the quality of the car.

2. High spe cific strength, tensile strength, yield strength, elongation and aluminum alloy casting. Experiments show that the specific strength of magnesium alloy is higher than that of aluminum alloy and steel. Therefore, magnesium alloy castings are about 25% lighter than aluminum castings without reducing component strength.

3. Easy to recycle. The recycled magnesium alloy can be dire ctly melted and then cast without reducing its me chanical properties. Magnesium alloy has a lower melting point than other metals. . In addition, magnesium alloy has good electromagnetic shieldling and beautiful appearance.

4. Good thermal conductivity, with good corrosion resistance, ele ctromagnetic shielding performance, radiation resistance, high pre cision machining, and good thermal conductivity, although the thermal conductivity of magnesium alloy is not as good as aluminum alloy, but nearly times higher than steel, 10 times higher than plastic materials. Therefore, magnesium alloy has been widely used in die-casting automobile wheels, which can effectively dissipate brake friction heat and improve brake stability.

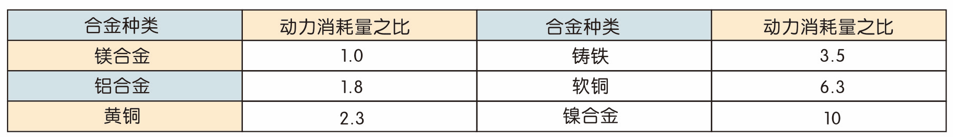

5. Good performance, welding and casting of magnesium alloy melting point, low heat capacity and phase change latent heat than aluminum alloy, melting energy dissipation is less, curing speed,|cw dynamic viscosity with good performance and dimensional stability, die-casting forming aluminium alloy die casting production cycle is short, easy to form BoJian parts, die casting minimum wall thickness can reach 0.1 5 mm, the affinity of magnesium and iron is small, The capa city of solid solution iron is low, and the mold life is 2 or 3 times higher than that of aluminum alloy. It is suitable for manufacturing all kinds of automobile die castings.

6. Good absorption performance for vibration and impact. It has good damping coefficient.Magnesium alloy has strong absorption capacity of vibration energy, and shock absorption performance is better than aluminum alloy and cast iron. It can reduce noise when used in driving and transmission parts, and reduce vibration when used in seats, wheels and steering wheels. It can absorb impact energy well after a collision, and improve the safety and comfort of cars.

7. Good sag resistance. Compared with other metals, magnesium alloy has strong deformation resistance, and the sag caused by impact is smaller than other metals.

8. It is easy to be machined. Magnesium alloy is very easy to be machined.